Microdispensing of adhesives

Perfect dispensing results in the μl area using the endless piston principle (Whitepaper)

High-precision results in microdispensing of adhesives are a supreme discipline in dosing technology. To wear the crown, a whole series of challenges must be mastered. Adhesives are becoming more and more complex and handling in automatic applications and dosing systems is becoming more difficult.

To reduce cycle times even further curing times become shorter and the systems more reactive. The mixing ratios are also becoming increasingly divergent. In addition, wide differences in viscosity between resin and hardener make it difficult to process 2-component adhesives.

The choice of the right dosing systems depends strongly on the behavior of the adhesive material. Above all, viscosity fluctuations, abrasive solids or a high shear sensitivity occur very frequently. It is extremely important for both adhesive experts and dispensing specialists to always be up to date and to find individual solutions for the customer.

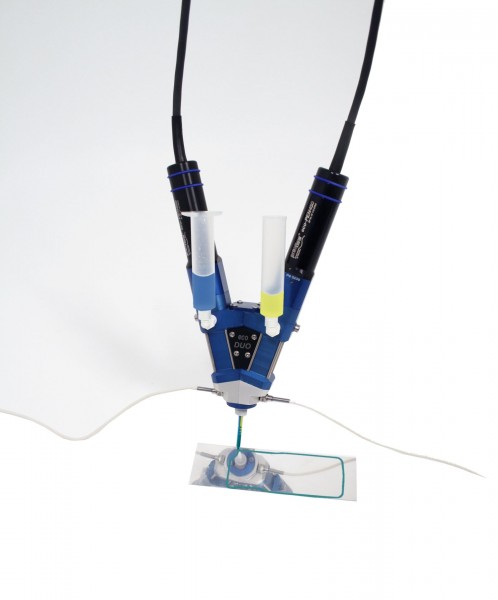

Picture 1: preeflow eco-PEN and eco-DUO dispenser family for microdispensing of low to high viscosity adhesives

Bonding is very popular and often replaces classic bonding methods such as welding, screwing and riveting. In this context the miniaturization of modules, assemblies and end products plays a decisive role. Adhesives are ideally suited for bonding a wide variety of materials together in the smallest of spaces: Fast, safe, durable and cost-effective. A multifunctional connection can be realized by bonding, e.g. in combination with temperature management, electrical conductivity or insulation.

The great demand for precise dosing of small and very small quantities prompted ViscoTec to establish the preeflow brand in 2008. With the purely volumetric eco-PEN and eco-DUO dispensers, dosing quantities from 0.001 ml can be realized.

This also includes the exact and reliable dosing of adhesives – regardless of whether 1- or 2-component materials.

Advantages of the endless piston principle

Thanks to the endless piston principle based on the progressive cavity technology, fluids and pastes are dosed volumetrically and handled extremely gently. So even solids-laden and shear-sensitive adhesives can be transported without problems – and with a repeatability of 99 % absolutely bubble-free!

The technology of the progressive cavity pump allows the dosing of numerous adhesives:

- UV & light-curing adhesives

- Thermosetting adhesives

- Anaerobic adhesives

- Highly filled adhesives with abrasive fillers

- Electrically conductive adhesives

- Shear-sensitive adhesives

- Thermal adhesives

- and many more

The special rotor-stator geometry of the progressive cavity technology and thus also of the preeflow dispensers enables pulsation-free dosing. Dosing quantities in the range from a few μl up to larger ml quantities can be dosed with the highest accuracy as dot, bead or potting application. Another decisive advantage of the endless piston principle is the automatic suck-back which prevents the material from dripping. This allows even very sensitive adhesives such as UV adhesives or anaerobic adhesives to be dosed. Due to the compact and weight-reduced design of the dispensers they can be integrated into almost all axis and robot systems. The dispensers can be operated and controlled as a complete dosing unit in systems.

Progressive cavity pumps belong to the family of positive displacement pumps. The principle is explained in the graphic on the left. The volume flow and the quantities to be dosed are directly proportional to the direction and number of rotation. The precise coordination of rotor and stator makes the dispenser pressure-tight which means there is no need for an additional valve. In this way, volumetric conveying can be guaranteed at any time. As a result, dosing smallest amounts can be handled very gently. A separate control allows programming of the speed for the operator. Once the characteristics of an adhesive are known, user-specific volumes can be programmed via the controller – completely independent of viscosity and temperature. With the microdispensers from preeflow, dosing with a volume flow of 0.1 to 60 ml/min is possible. In addition, both the 1- and 2-component dispensers can be used as hand-held devices but also in fully automated processes.

Picture 2: ViscoTec endless piston principle

Further advantages offered to the customer are:

– Dosing independent of pressure, time and temperature

– A worldwide, specialized distributor network

– Low maintenance costs

– Absolute process reliability

– High planning reliability

– Valveless tight technology

– Very easy handling

– Worldwide support 24/7

– More than 10 years of experience in microdispensing technology

Application examples of microdispensing of adhesives

Microdispensing of adhesives is used in optics & photonics, biochemistry, photovoltaics, SMD/SMT, semiconductor production, medical technology, LCD/LED and many other industries. For example, in optical bonding a clear adhesive is applied between the glass layers of a touch panel display. An absolute no-go in this application is the color change of the adhesive during the application. preeflow dispensers can easily overcome this challenge.

Picture 3: Bonding application: preeflow eco-DUO 2-component dispenser at loudspeaker bonding

Especially in the field of adhesive dosing, preeflow has extensive knowledge in dosing technology, many innovations and great successes. preeflow products are integrated into dosing applications worldwide and can be individually adapted to the needs of customers. The motto always applies: “Smaller, more precise, more economical”.

Retrieve specific product information, see pictures on our Product Site

Tags In

Categories

- Dispensers (38)

- Dopag (8)

- Events (3)

- Markets (1)

- Meter Mix (8)

- News (4)

- Precifluid (4)

- Preeflow (34)

- Uncategorized (20)

- Viscotec (39)