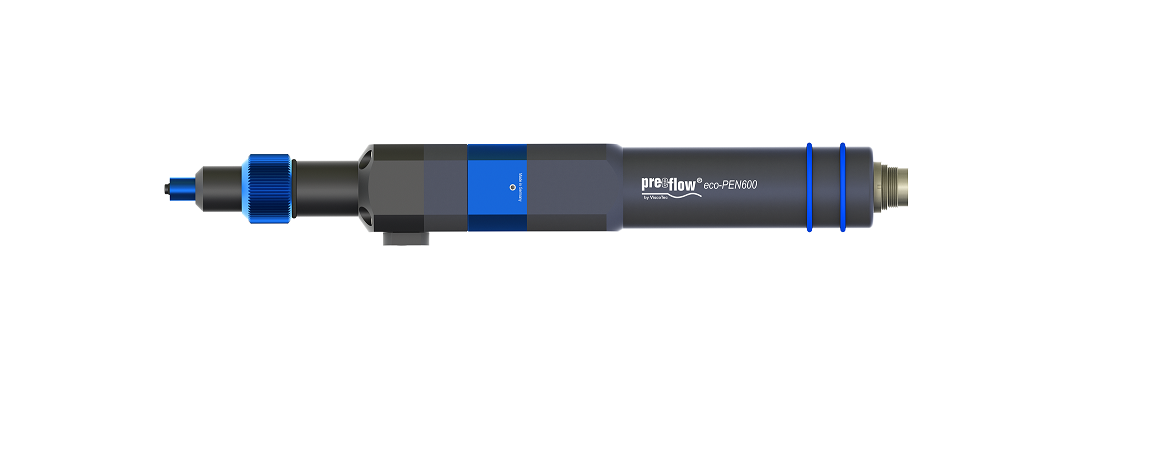

eco-PEN600 Dispenser

Volume dispenser preeflow® eco-PEN600

Endless piston principle, flow rate 1,4 up to 16 cc/min

Datasheet

Product Description

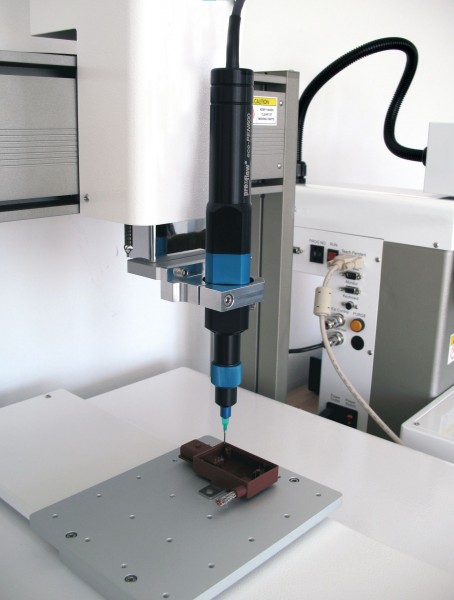

The preeflow® eco-PEN600 is a volumetric dispensing system. In this system the proven technology of the eccentric screw pump is designed and manufactured in a miniaturized version. New manufacturing processes and materials are used to convert the complex geometries of the screw auger and the stator into this small design. Material can flow and be metered in very small volumes, fully volumetrically, out of the valve and also in “reverse” inward fashion. This ensures a very clean and precise dispensing of the material.

Functionality

The preeflow® eco-PEN600 is a rotating, pressure-tight displacement system. It consists of a stainless steel rotor and an elastomer stator which together form a self-sealing system. This creates individual, self-contained volume “chambers”. As a result of the rotational movement of the stator, the volume “chambers” are pushed further, thereby generating the material flow. For low-viscosity products, the system is self-priming.

- Dimensions (WxHxD) 34x34x274 mm

- Shipping weight1.15 kg

- Operation: volumetric

- Material inlet: 1/4 Inch

- Operating pressure (min.) 0 bar

- Wetted part materials: HD-POM / Stainless Steel

- Weight: 750 g

- Material outlet: Luer-Lock with O-Ring

- Voltage: 18 – 24 V DC

- Flow rate: 1,4 – 16 ml/min

- Dispensing volume (min.): 0,015 ml

- Fluid pressure (max.): 20 bar

Applications: adhesives, UV adhesive, anaerobe, oils, alcohol/methanol, fats/greases, silicone, solder paste, seals, epoxy, thermoconductive paste

Not good for: cyanoacrylates, bases, solvents, acid

Relevant Accessories: Valve controller: Eco-Control EC200-K or Eco-Control EC200-B or for speed control “plug n dose” is required.

Which product do you require?

Together we will find the perfect solution for you.