A Variety of Dispensers for Micro Dispensing Applications

Covering the entire production process with one technology

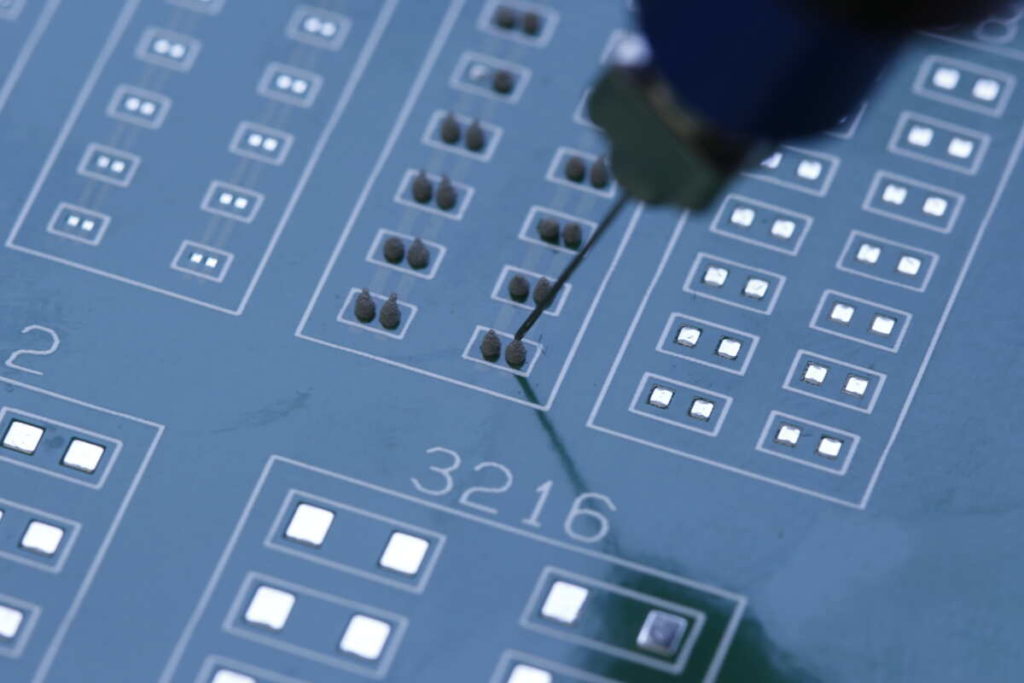

Dispensing small and smallest quantities with volumetric precision and speed often presents major challenges for companies in the medical technology, automotive, electronics, biochemistry, and photonics industries. It is not uncommon for industrial manufacturing companies to integrate various dispensing systems from different suppliers into their lines in order to meet the chemical and physical properties of all materials to be mixed and dispensed. The preeflow brand, whose dispensing technologies can process silicones, adhesives, greases, oils, resins, sealants, or pastes and much more in the currently widest possible spectrum, works reliably and accurately even at extremely high cycle rates.

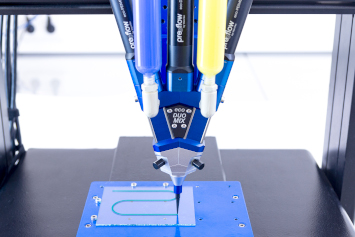

One-component dispensing systems (eco-PEN), spray dispensers (eco-SPRAY) and two-component variants (eco-DUO) are available and based on the operating principle of progressive cavity pumps. They are equally suitable for manual operation and fully automated use. The so-called endless piston principle ensures pulsation-free and purely volumetric dispensing and delivers material of varying viscosity, unchanged throughout the entire process.

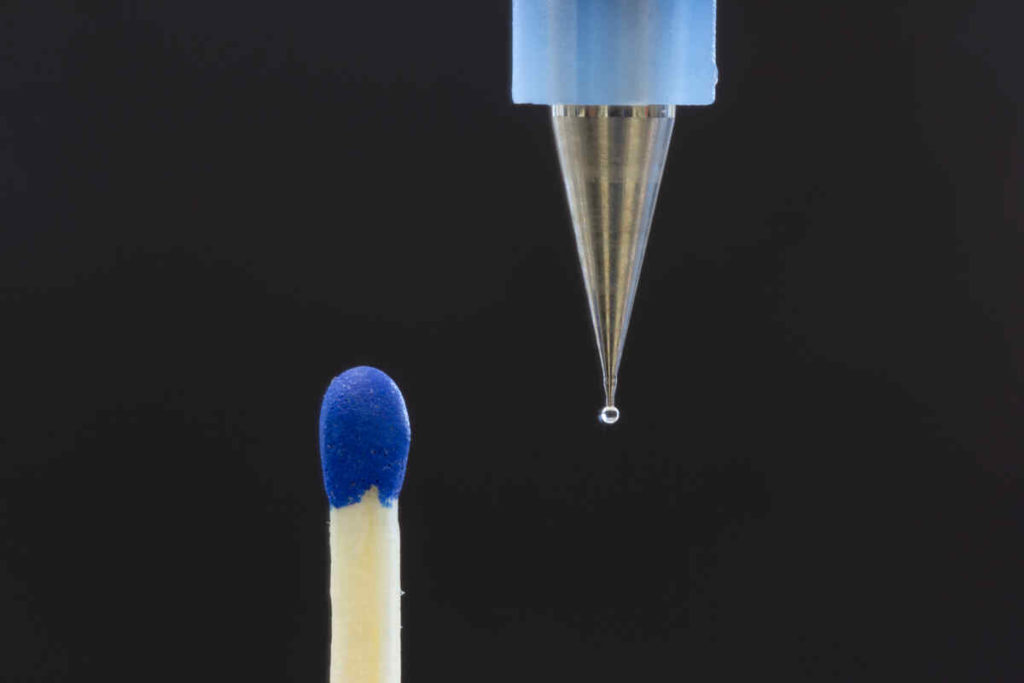

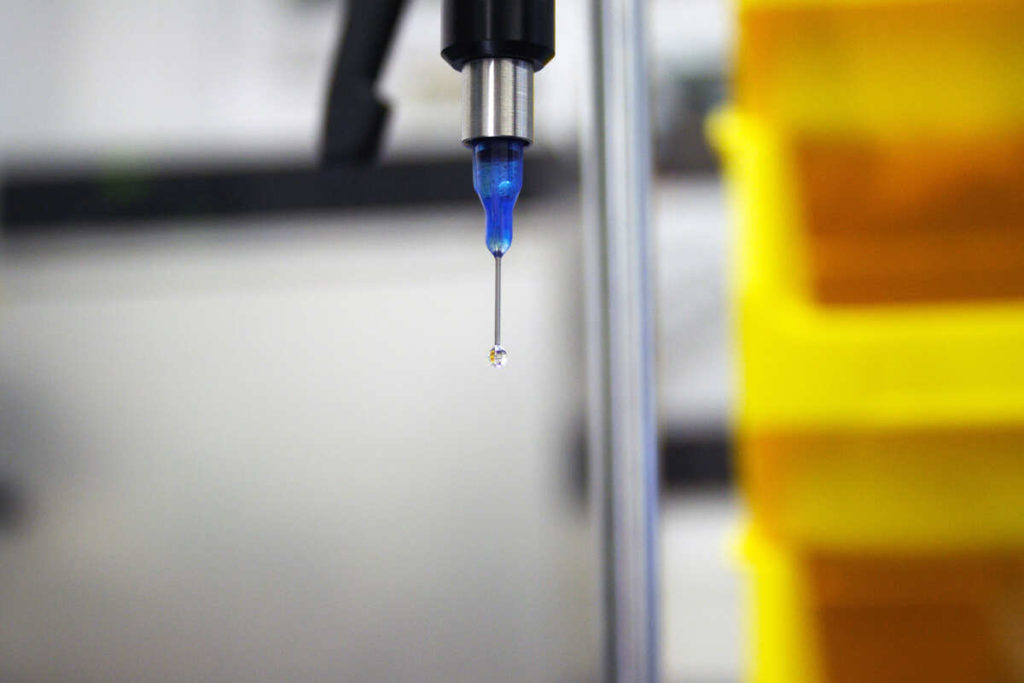

The above-mentioned designs are continuously adapted by an internal research and development team to an increasingly wide range of industrially processable materials, considering parameters such as material composition and its viscosity. The dispensing of adhesives – light-curing, thermosetting, anaerobic, shear-sensitive – is just as simple as the application of solder pastes, the application of thermal pastes or the dispensing of LED resins, to name but a few. The programmable suck-back effect guarantees a clean, controlled thread break with any material, without dripping.

One solution for each dispensing task

Constructively, and in view of the to control technology, different systems are designed specifically for different industrial tasks.

Like the other two dispensing systems, the spray dispenser is based on a rotating, completely pressure-tight, displacement system. Defined rotary movements of the rotor displace the material volumetrically in the stator and convey it into a processor-controlled low-flow spray chamber, where precise atomization and spraying takes place. The spray dispenser can be used in manual or automated mode, using low to high viscosity material to create a well-defined edge and with minimal overspray, which can be atomized either continuously or sporadically.

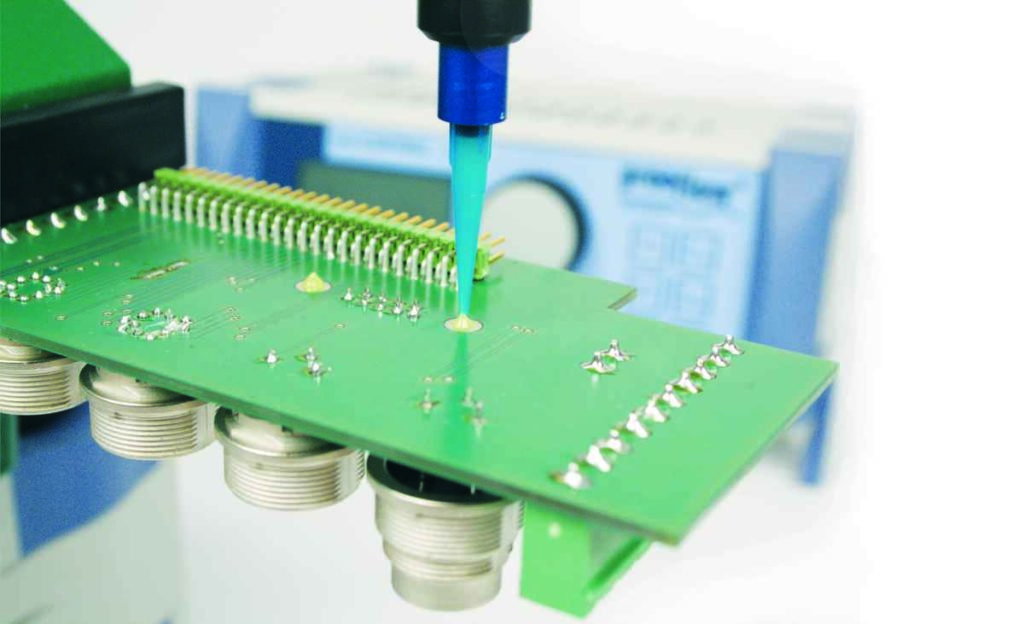

The one-component dispenser was designed for single-component fluid dispensing. Precise dispensing of aqueous to pasty liquids is possible with even the smallest quantities. The technical design allows the one-component dispenser to be used independently of viscosity fluctuations and ensures clean dispensing – in manual operation, as a desktop device, or automated via a control unit.

With two-component dispensers, systems for the traditional processing of various two-component materials can be selected, or a model that is technically adapted to the requirements of materials which are extremely difficult to mix. The classic two-component dispenser is available in three designs, determined by the quantity to be dispensed. Application is either via static mixing elements, in which the two components are mixed before application. Or – perfect for all viscous two-component materials that are difficult to mix – via a mixing capsule with optimized dead space.

Streamlined warehousing and reduced service costs

The technologies mentioned above can be used as stand-alone units or according to the requirements in a production line throughout the entire process. All systems have the same control system with integrated pressure monitoring and enable the setting of dispensing quantities, mixing ratio and even dispense time. Each control unit is calibrated, and the various functions parameterized via a standardized terminal program. An integrated motor monitoring system serves as an overload protection for the dispensers and can process error messages and pass them on to a higher-level system if required.

If manufacturers use the different dispensers at different stages in a process, such as traditional bonding and the subsequent spray sealing of the fully assembled board, they benefit from the same active principle at both process steps and invest in process reliability through homogeneous structures. Finally, the use of systems from one brand can significantly simplify the storage of consumables and spare parts. The planning of service calls becomes much easier when using the same technology and ultimately results in a reduction in maintenance costs.

Dækker hele produktionsprocessen med én teknologi

Dispensering af små og meget små mængder med volumetrisk præcision og hastighed udgør ofte store udfordringer for virksomheder inden for medicinsk teknologi, bilindustrien, elektronik, biokemi og fotonikindustrien. Det er ikke ualmindeligt, at industrielle fremstillingsvirksomheder integrerer forskellige doseringssystemer fra forskellige leverandører i deres linjer for at imødekomme de kemiske og fysiske egenskaber af alle materialer, der skal blandes og dispenseres. Preeflow-mærket, hvis dispenseringsteknologier kan behandle silikoner, klæbemidler, fedtstoffer, olier, harpikser, tætningsmidler eller pastaer og meget mere i det i øjeblikket bredest mulige spektrum, fungerer pålideligt og præcist selv ved ekstremt høje cyklushastigheder.

En-komponents doseringssystemer (eco-PEN), spraydispensere (eco-SPRAY) og to-komponentvarianter (eco-DUO) er tilgængelige og baseret på driftsprincippet for progressive hulrumspumper. De er lige så velegnede til manuel betjening og fuldautomatisk brug. Det såkaldte endeløse stempelprincip sikrer pulsationsfri og rent volumetrisk dispensering og leverer materiale med varierende viskositet uændret gennem hele processen.

Ovennævnte designs tilpasses løbende af et internt forsknings- og udviklingsteam til en stadig bredere vifte af industrielt forarbejdelige materialer under hensyntagen til parametre som materialesammensætning og dens viskositet. Dispensering af klæbemidler – lyshærdende, termohærdende, anaerob, forskydningsfølsom – er lige så enkel som påføring af loddepasta, påføring af termopasta eller dispensering af LED-harpikser, for blot at nævne nogle få. Den programmerbare sugeffekt garanterer en ren, kontrolleret trådbrud med ethvert materiale uden dryp.

Én løsning til hver dispenseringsopgave

De forskellige systemer er designet specifikt til forskellige industrielle opgaver.

Ligesom de to andre dispensersystemer er sprøjtedispenseren baseret på et roterende, fuldstændigt presstæt forskydningssystem. Definerede rotorbevægelser i rotoren forskyder materialet volumetrisk i statoren og transporterer det ind i et processorstyret sprøjtekammer med lavt flow, hvor præcis forstøvning og sprøjtning finder sted. Spraydispenseren kan bruges i manuel eller automatiseret tilstand ved hjælp af materiale med lav til høj viskositet til at skabe en veldefineret kant og med minimal oversprøjtning, som kan forstøves enten kontinuerligt eller sporadisk.

1-komponentdispenseren er designet til enkeltkomponent væskedispensering. Præcis disepnsering af vandige til pastaagtige væsker er mulig i selv de mindste mængder. Det tekniske design gør det muligt at bruge en-komponentdispenseren uafhængigt af viskositetsudsving og sikrer en ren dispensering – i manuel betjening, som en stationær enhed eller automatiseret via en styreenhed.

Med 2-komponent dispensere kan der vælges systemer til traditionel behandling af forskellige tokomponentmaterialer eller en model, der er teknisk tilpasset kravene til materialer, som er ekstremt vanskelige at blande. Den klassiske 2-komponent dispenser fås i tre designs, bestemt af den mængde, der skal dispenseres. Påføring sker enten via statiske blandingselementer, hvor de to komponenter blandes inden påføring. Eller – perfekt til alle tyktflydende to-komponentmaterialer, der er vanskelige at blande – via en blandekapsel med optimeret frivolumen.

Strømlinet lager og reducerede serviceomkostninger

De ovennævnte teknologier kan bruges som enkeltstående enheder eller i henhold til kravene i en produktionslinje gennem hele processen. Alle systemer har det samme kontrolsystem med integreret trykovervågning og muliggør indstilling af doseringsmængder, blandingsforhold og endda dispenseringstid. Hver styreenhed er kalibreret, og de forskellige funktioner parametriseres via et standardiseret terminalprogram. Et integreret motorovervågningssystem fungerer som en overbelastningsbeskyttelse for dispenserne og kan behandle fejlmeddelelser og videregive dem til et højere niveau-system, hvis det kræves.

Hvis producenter bruger de forskellige dispensere på forskellige stadier i en proces, såsom traditionel limning og den efterfølgende sprayforsegling, drager de fordel af det samme aktive princip i begge procestrin og investerer dermed i procespålidelighed gennem homogene strukturer. Endelig kan brugen af systemer fra ét mærke forenkle opbevaringen af forbrugsvarer og reservedele betydeligt. Planlægningen af service bliver meget lettere, når du bruger den samme teknologi og det resulterer i sidste ende i en reduktion af vedligeholdelsesomkostninger.

Original article here

This article has been published on www.metal-supply.dk

Categories

- Dispensers (38)

- Dopag (8)

- Events (3)

- Markets (1)

- Meter Mix (8)

- News (4)

- Precifluid (4)

- Preeflow (34)

- Uncategorized (20)

- Viscotec (39)