Avoid hidden costs when equipping with dispensing technology

DC rotors from preeflow for profitable and effective investments

A forthcoming investment in new process equipment with dispensing technology brings with it a number of questions. One issue may be: Does the new equipment work properly – with everything included? Is it reliable? Are the dispensing results perfectly repeatable? Are the required quantities applied with precision in the specified time? An equally important issue: What will it cost? What is the total cost of ownership? What other costs, in addition to the initial investment, can be expected? In order to avoid unpleasant surprises, it is worth getting in touch with the dispensing technology manufacturer’s contact person at an early stage of the project. This way, all costs can be made visible from the start.

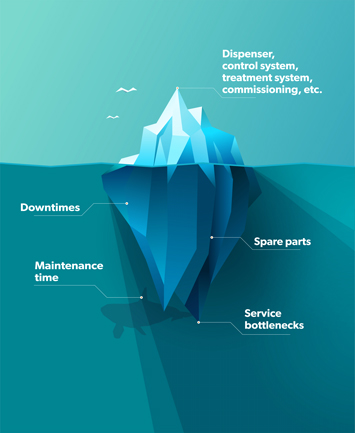

Let us compare it to looking at an iceberg. At the top you can see only the investment in the equipment itself. Depending on the need: Dispenser, control system, treatment system, commissioning, etc. But other factors are lurking beneath the surface of the water. What happens after the initial operation of a system? You may be faced with maintenance time, spare parts or downtime, depending on the availability of spare parts, service, etc. And all this can be associated with further costs.

A reliable partner knows the hidden areas below the surface of the water. Together with you, efficient and rewarding products can be put together. At preeflow, for example, work is done daily to reduce the areas below the surface of the water as much as possible. The portfolio is constantly being developed to meet your specific and individual needs for your process. The goal is: To provide an exceptionally good experience, together with your investment.

Best choice according to ROI

Let us go into more detail to determine the return on investment (ROI). So, after what period of time or after what quantity of dispensing operations have I covered all the costs of my initial investment? Exact data depends on the material to be dispensed, the dispensing equipment used, the cycle times, the process parameters and much more.

In most cases, you will receive at least two offers. Why the one that is cheaper at first sight is not necessarily the better one in the long run, is shown by the example of our DC rotors:

The right dispensing equipment is being sought for the dispensing of a heat conducting material on behalf of a customer. The material is a highly filled, abrasive, one-component epoxy. It is responsible for supporting the thermal management in an electronic device. The dispensing challenges are to avoid air bubbles, to handle the usually highly viscous materials and to achieve reliable, repeatable results despite the highly abrasive fillers.

Various system providers promise to fulfil all the requirements and to be able to implement dispensing with their system. Among them is preeflow – the eco-PEN was recommended for this application. Equipped with a special stator material and a Diamond Coated Rotor (DC Rotor for short) – developed for highly abrasive (and sometimes heat-conductive) materials. Even for the most challenging applications. The Diamond Coating, specially developed by ViscoTec, is a new type of multi-layer coating that has a surface hardness of well over 2000 HVpi. In addition to the extreme hardness, the coating also has tribologically optimized properties. Hard fillers can be dispensed with the DC rotors and the sliding properties and friction values are optimized – for the best possible overall performance.

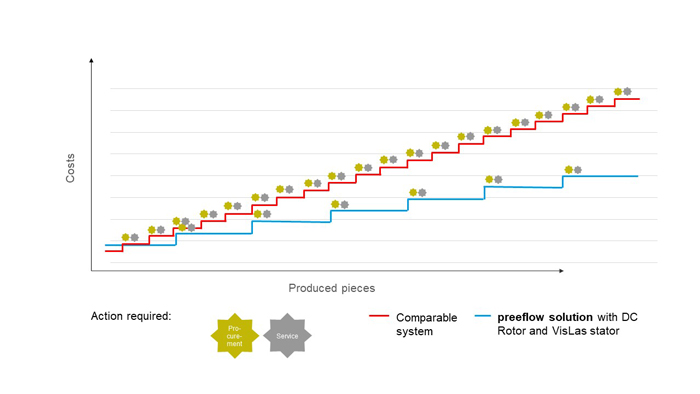

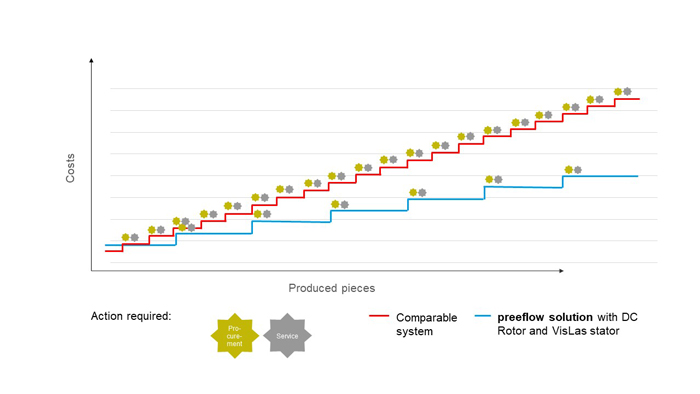

Other suppliers may use the same or similar dispensing technology, but their standard products cannot withstand the demands of the highly abrasive dispensing materials in the actual process for long. Conventional dispensing systems are quickly brought to their limits when processing thermal pastes. The replacement of spare parts follows not long after. This also includes costs for retrofitting and the ordering process. This is clearly shown in the following graph. It shows the costs in relation to the number of parts produced and the number of dispensing processes.

The initial investment for the preeflow solution with special equipment is initially somewhat higher, but from the very first spare part change, it is the most economical and effective solution. Thanks to the robust components in the one- or two-component dispensers, maintenance and spare parts changes are reduced by two to three times. This saves you time and money. The process becomes more reliable overall.

To calculate the ROI for your specific application, long-term tests can be helpful. preeflow implements these tests under process conditions in its in-house technical center. In addition to the headquarters in Germany, numerous distributors and 5 subsidiaries worldwide support implementation and decision-making – one of them is most likely not far from you. Benefit from a guaranteed delivery time of spare parts within 24 hours, worldwide, from more than 20 years of experience in micro dispensing and from an outstanding service! It is up to you to make the best choice.

Undgå skjulte omkostninger, når du producerer med dispenseringsteknologi

Vores udstyr fra preeflow giver rentable og gode investeringer

En kommende investering i nyt produktionsudstyr medfører en række spørgsmål. Et problem kan være: Virker det nye udstyr korrekt – med alt inkluderet? Er det pålideligt? Kan dispenseringsresultaterne gentages med den påkrævede nøjagtighed igen og igen? Påføres de nødvendige mængder med præcision inden for den angivne tid? Et lige så vigtigt spørgsmål: Hvad vil det koste? Hvad er de samlede ejeromkostninger? Hvilke andre omkostninger, udover den oprindelige investering, kan forventes? For at undgå ubehagelige overraskelser er det en god idé at komme i kontakt med producentens kontaktperson i en tidlig fase af projektet. På denne måde kan alle omkostninger synliggøres fra starten.

Lad os sammenligne det med at se på et isbjerg. Øverst kan du kun se investeringen i selve udstyret. Afhængigt af behovet: Dispenser, kontrolsystem, behandlingssystem, idriftsættelse osv. Men andre faktorer lurer under vandoverfladen. Hvad sker der efter den første drift af et system? Du kan stå over for vedligeholdelsestid, reservedele eller nedetid, afhængigt af tilgængeligheden af reservedele, service osv. Og alt dette kan være forbundet med yderligere omkostninger.

En pålidelig partner kender de skjulte områder under vandoverfladen. Sammen med dig kan effektive og givende produkter sammensættes. Hos preeflow arbejdes der dagligt for at reducere områderne under vandoverfladen så meget som muligt. Porteføljen udvikles konstant for at imødekomme dine specifikke og individuelle behov for din proces. Målet er: At give en usædvanlig god oplevelse sammen med din investering.

Bedste valg ifølge ROI

Lad os gå mere i detaljer for at bestemme investeringsafkastet (ROI). Så efter hvilken periode eller efter hvilken mængde dispenseringsopgaver har jeg dækket alle omkostningerne ved min oprindelige investering? De nøjagtige data afhænger af det materiale, der skal dispenseres, det anvendte dispenseringsudstyr, cyklustiderne, procesparametrene og meget mere.

I de fleste tilfælde modtager du mindst to tilbud, når du skal opstarte et nyt projekt. Hvorfor tilbuddet, der er billigere ved første øjekast, ikke nødvendigvis er det bedste i det lange løb, viser eksemplet nedenfor:

Det rette dispenseringsudstyr søges til dispensering af et varmeledende materiale på vegne af en kunde. Materialet er en slibende en-komponent epoxy. Materialet skal bruges til at understøtte den termiske styring i en elektronisk enhed. Dispenseringsudfordringerne er at undgå luftbobler, at håndtere de normalt meget tyktflydende materialer og at opnå pålidelige, gentagelige resultater på trods af de stærkt slibende fyldstoffer i materialet.

Forskellige systemudbydere lover at opfylde alle kravene og at kunne implementere dispensering med deres system. Blandt dem er preeflow. Vores eco-PEN blev anbefalet til denne applikation, da denne er udstyret med et specielt statormateriale og en Diamond Coated Rotor (DC Rotor for kort) udviklet til meget slibende og varmeledende materialer, selv til de mest udfordrende applikationer. Diamond Coating, specielt udviklet af ViscoTec, er en ny type flerlagsbelægning, der har en overfladehårdhed på godt 2000 HVpi. Udover den ekstreme hårdhed har belægningen også tribologisk optimerede egenskaber. Hårde fyldstoffer kan dispenseres med DC-rotorerne, og glideegenskaberne og friktionsværdierne optimeres – for den bedst mulige samlede ydelse.

Andre leverandører kan bruge den samme eller lignende dispenseringsteknologi, men deres standardprodukter kan ikke modstå kravene fra de meget slibende dispenseringsmaterialer i selve processen i lang tid. Konventionelle dispenseringssystemer bringes hurtigt til deres grænser ved behandling af termiske pastaer. Udskiftning af reservedele følger hurtigt herefter. Dette inkluderer også omkostninger til eftermontering og selve bestillingsprocessen. Dette er tydeligt vist i følgende graf. Den viser omkostningerne i forhold til antallet af producerede dele og antallet af dispenseringsprocesser.

Ved første øjekast er investeringen i preeflow-løsningen i første omgang noget højere, men fra den allerførste udskiftning af reservedele er det den mest økonomiske og effektive løsning. Takket være de robuste komponenter i en- eller tokomponentdispenserne reduceres vedligeholdelse og udskiftning af reservedele med to til tre gange. Dette sparer dig tid og penge. Processen bliver generelt mere pålidelig.

For at beregne ROI for din specifikke applikation kan langsigtede tests være nyttige. Disse tests kan foretages hos preeflow i samarbejde med Scanmaster, så du får det bedst mulige grundlag til at træffe den rigtige beslutning ang. din nye investering. Vi er klar til at hjælpe dig. Det er op til dig at træffe det rette valg.

Categories

- Dispensers (38)

- Dopag (8)

- Events (3)

- Markets (1)

- Meter Mix (8)

- News (4)

- Precifluid (4)

- Preeflow (34)

- Uncategorized (20)

- Viscotec (39)